AlNiCo is one of the earliest permanent magnet materials developed. It is an alloy composed of aluminum, nickel, cobalt, iron and other trace metal elements. Al - ni - co permanent magnet material was developed successfully in the 1930s. At that time, its magnetic properties are the best, and the temperature coefficient is small, so it is most widely used in permanent magnet motors.

Permanent magnet Alnico is an alloy of iron with aluminum (Al), nickel (Ni), cobalt (Co) and a small number of other magnetically enhanced components added to iron.

The English term "Alnico" is a combination of the element symbols of the three main additions.

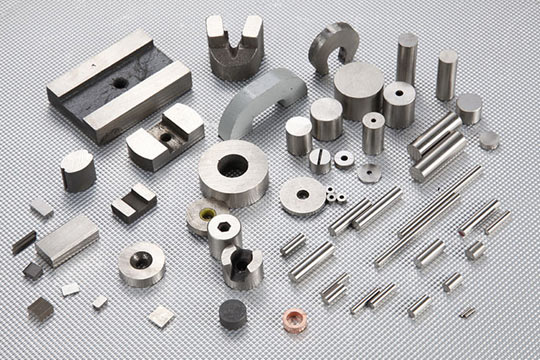

AlNiCo alloy has high coercivity and high Curie temperature, are hard and brittle and cannot be cold worked and must be processed by a casting or Sintering process.

The aluminum-nickel-cobalt alloy can produce a magnetic field of up to 0.15 tesla.

As an example of an intermediate anisotropic cast alnico-Cobalt alloy, Alnico-6 is composed of 8%Al, 16%Ni, 24%Co, 3%Cu, 1%Ti, and all the others are Fe. Alnico-6 has a maximum magnetic energy product (BHmax) of 3.9 Megagauss-Oesteds (MG·Oe), a persistence of 780 Oersted, a Curie temperature of 860 °C, and a maximum operating temperature of 525 °C.

In 1931, Mishima, a Japanese materials expert, discovered an AlNiCo alloy (58% Fe, 30%Ni, 12%Al) of a specific composition that was twice as coercive as the best magnetic steels of the period. Before the discovery of rare-earth magnets in the 1970s, alnico was the strongest permanent magnet material.