Soft magnetic materials are magnetic materials whose magnetization occurs when HC is less than 1000A / m. Soft magnetic materials are characterized by low coercivity, high permeability, high saturation magnetic induction and minimal eddy current loss. Soft magnetic materials are not only easy to magnetize, but also easy to demagnetize, which can achieve the maximum magnetization with the minimum external magnetic field.

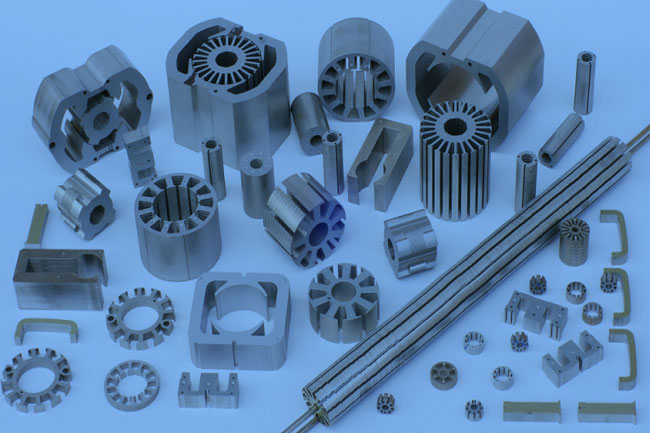

The main function of soft magnetic materials is to transfer and transmit magnetic and electromagnetic energy. Therefore, it is widely used in electrical equipment and radio electronics industry, such as transformer, generator, motor, electromagnet, all kinds of relay and inductor, reactor, sensor core, magnetic shield, magnetic head, magnetic recording medium, computer core, electromagnetic chuck, magnetic sensor (such as magnetocaloric material as switch), etc. Soft magnetic material is one of the important magnetic materials in aerospace, national defense and military industry.

| FeCoV Soft Magnetic Alloy | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Grade | Level | Magnetic Induction | Coercive | |||||||

| B400 | B800 | B1600 | B2400 | B4000 | B8000 | Hc | ||||

| T(Min) | A/m(Max) | |||||||||

| 1J21 | Ⅰ | 1.8 | 2.0 | 2.1 | 2.3 | 2.4 | ҆ | 80 | ||

| Ⅱ | 1.8 | 2.0 | 2.1 | 2.3 | 2.4 | ҆ | 48 | |||

| 1J22 | ҆ | 1.6 | 1.8 | 2.0 | 2.1 | 2.2 | 2.2 | 128 | ||

| FeCoV Magnetic Hysteresis Alloy | ||||||||||

| Grade | Intermediate Species | Level | B(m)ғ1.23±0.02T | B(m)ғ1.36±0.02T | B(m)ғ1.42±0.02T | |||||

| Hm | Pro (105erg/ cm3Hz) | Hm | Pro | Hm | Pro (105erg/ cm3Hz) | |||||

| (A/m) | (A/m) | (105erg/ cm3Hz) | (A/m) | |||||||

| 2J4 | Cold rolled strip | Ⅰ | ≤4400 | ≥1.44 | ≤4800 | ≥1.65 | ≤5200 | ≥1.85 | ||

| 5174A/m | 9552A/m | |||||||||

| Ⅱ | Br | Hc | Pro | Br | Hc | Pro | ||||

| (T) | (A/m) | (105erg/cm3Hz) | (T) | (A/m) | (105erg/cm3Hz) | |||||

| ≥1.1 | ≥3582 | ≥1.8 | ≥1.1 | ≥3582 | ≥2.6 | |||||

| FeNi Soft Magnetic Alloy | ||||||||||

| Grade | Intermediate Species | Level | Thickness/Diameter (mm) | U0.4 | Um | Hc | Bs | |||

| mH/m(Min) | A/m(Max) | T(Min) | ||||||||

| 1J50 | Cold rolled strip | Ⅱ | 0.10-0.19 | 3.8 | 43.8 | 12 | 1.5 | |||

| 0.20-0.34 | 4.4 | 56.3 | 10.4 | |||||||

| 0.35-0.50 | 5 | 65 | 8.8 | |||||||

| 0.51-1.00 | 5 | 50 | 10 | |||||||

| 1.10-2.50 | 3.8 | 44 | 12 | |||||||

| —— | 3~22 | 3.1 | 31.3 | 14.4 | 1.5 | |||||

| —— | 8~100 | 3.1 | 31.3 | 14.4 | 1.5 | |||||

| Grade | Intermediate Species | Level | Thickness/Diameter (mm) | U0.8 | Um | Hc | Bs | |||

| mH/m(Min) | A/m (Max) | T(Min) | ||||||||

| 1J79 | Cold rolled strip | I | 0.10-0.19 | 28 | 190 | 1.2 | 0.75 | |||

| 0.20-0.34 | 31 | 250 | 1.2 | |||||||

| 0.35-1.00 | 38 | 280 | 1.0 | |||||||

| 1.10-2.50 | 31 | 230 | 1.2 | |||||||

| FeNi Soft Magnetic Alloy | ||||||||||

| Grade | Intermediate Species | Level | Thickness/Diameter (mm) | U0.4 | Um | Hc | Bs | |||

| mH/m(Min) | A/m(Max) | T(Min) | ||||||||

| 1J79 | —— | 3ӗ22 | 25 | 125 | 2.4 | 0.75 | ||||

| —— | 8ӗ100 | 25 | 125 | 2.4 | ||||||

| 1J79C | Cold rolled strip | —— | —— | 37.5 | 125 | 1.6 | ||||

| 1J85 | Cold rolled strip | I | 0.20-0.34 | 50 | 225 | 1.2 | 0.7 | |||

| 0.35-1.00 | 62.5 | 312.5 | 0.8 | |||||||

| 1.10-2.50 | 50 | 187.5 | 1.2 | |||||||

| 2.51-3.00 | 43.8 | 150 | 1.4 | |||||||

| —— | 3ӗ22 | 37.5 | 125 | 1.6 | ||||||

| —— | 8ӗ100 | 37.5 | 125 | 1.6 | ||||||

| 1J85C | Cold rolled strip | —— | —— | 50 | 125 | 1.6 | 0.68 | |||

| 1J95 | Cold rolled strip | —— | —— | 50 | 125 | 1.6 | 0.55 | |||

| Anti--corrosion Soft Magnetic Alloy | ||||||||||

| Grade | MagneRc Induction | Remanence Induction | Um | Hc | ||||||

| B240 | B400 | B800 | B2400 | B3200 | Br240 | Br2400 | Br3200 | mH/m(Min) | A/m(Max) | |

| T(Min) | T(Max) | |||||||||

| 1J117 | 0.9 | ҆ | 1.0 | ҆ | 1.25 | ҆ | ҆ | ҆ | ҆ | 80 |

| Cr17NiTi | ҆ | 0.9 | 1.0 | 1.2 | ҆ | ҆ | 0.95 | ҆ | 3.75 | 80 |

| High Permeability Soft Magnetic Alloy | ||||||||||

| Grade | Intermediate Species | Level | Thickness/ Diameter (mm) | 0.001 | Um | Hc | Br | |||

| mH/m(Min) | A/m(Max) | T(Max) | ||||||||

| S1J81A | Cold rolled strip | —— | —— | 50 | 150 | 1 | 0.4 | |||

| —— | —— | 40 | 150 | 1 | 0.4 | |||||

Service every customer with care & professional.

Professional Production Base

AEMagnets is equipped with a complete set of advanced equipments and processing facilities in particular high standard cleaning room.

Strict Quality Control - ISO9001

We runs a strict quality control system involving raw materials selection, production control, product inspection, fine packing.

Timely and Attentive Service

We strive to provide fast and efficient service to meet your deadlines and provide full technical and after-sales service support.