Are you looking for a reliable Ferrite magnets manufacturer, are you searching for the strongest magnets for your application, or even expecting design for your own specificiation, I am glad you have come to the right place.

With over 20 years design and manufacturing experience, AEMagnets is a leading Ferrite magnets supplier, serve to different industies with various sizes and shapes. Applications such as magnetic push bearings, magnetic separators, speakers, microwave devices, the highest working temperatures up to 550 degree.

Are you eager to explore more about us, are you ready to discuss with us, let's start!

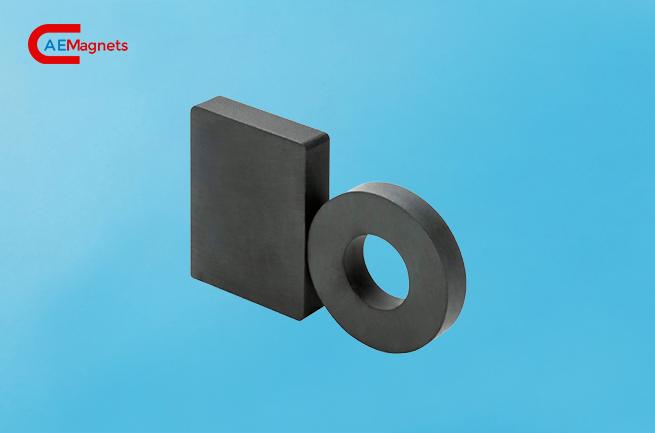

Ferrite Y20 with size of Diameter 35*5mm

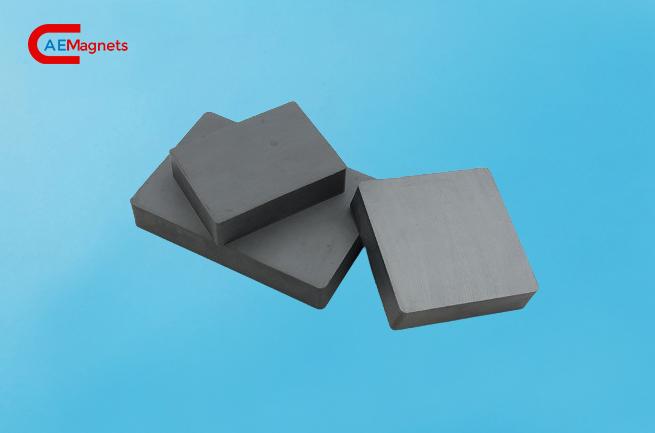

Ferrite Y30 with size of 35*35*5mm

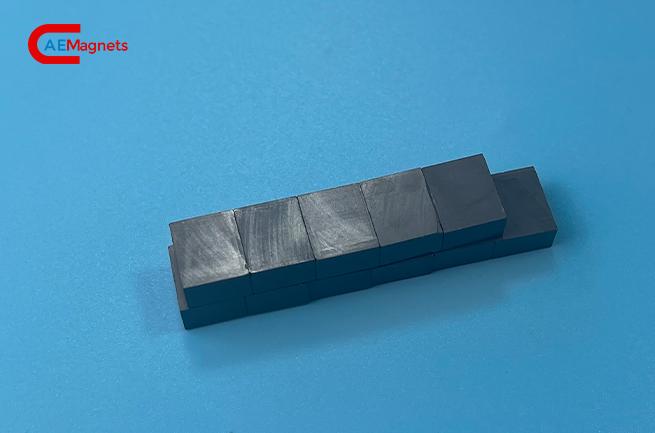

Ferrite Y35 with size of 12*10*6mm

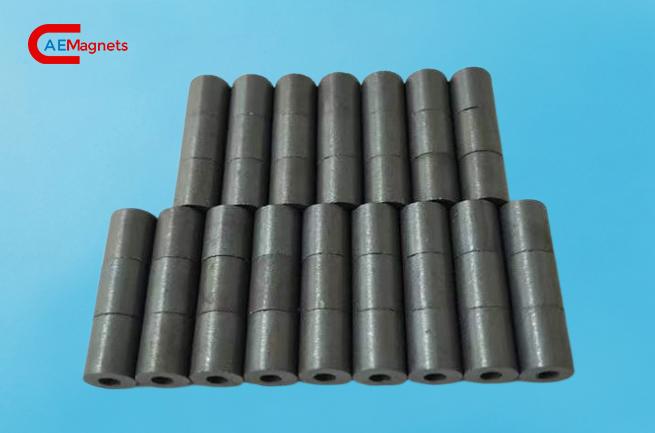

Ferrite Y28 with size of OD16*10*4mm

Ferrite Y32 with size of OD12*5*16mm

Ferrite 25 with size of Diameter 12*3mm

Ferrite Y33 with size of 20*8*4mm

Ferrite Y40 with size of 26*20*6mm

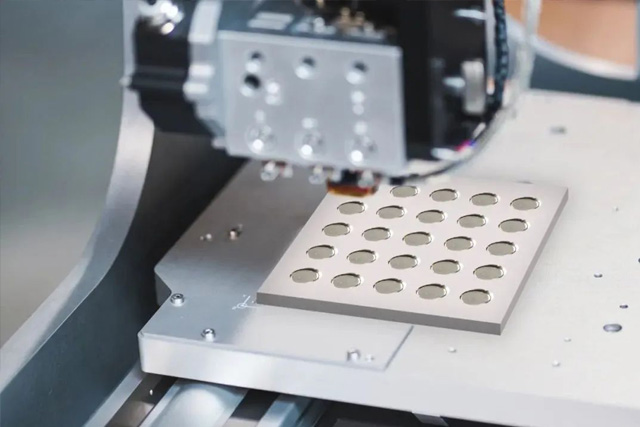

At AEMagnets, we understand every customer has individual needs and specifictions for the Ferrite magnets, that's why we insit on customize for our client, not only for design but also for the manufacruring and service.

Sizes and shapes: Ferrite magnets come in a variety of sizes and shapes to meet the diverse needs of different applications. It's important to note that the size and shape of Ferrite magnets are chosen based on the intended application, available space, and required magnetic strength.

Grades & magnetic strength: We provide a wide range of grades, including C Grades (C1, C5, C8, etc.) to widespread used Y Grades (Y20, Y30, Y35, etc.), also Hard Ferrite Grades (e.g., HF26/18). Additionally, the application requirements, such as operating temperature, magnet shape, and dimensional constraints, should be taken into account when choosing the appropriate grade. and magnetic strength.

Working temperatures: Ferrite magnets, have relatively good temperature stability compared to some other types of magnets. However, their magnetic properties can be affected by temperature extremes. Operating Temperature Range: The typical operating temperature range for standard ferrite magnets is approximately -40°C to 250°C (-40°F to 480°F). Curie Temperature: The Curie temperature (Tc) is a critical temperature for magnets. Above this temperature, the magnet will start to lose its magnetic properties. For ferrite magnets, the Curie temperature is generally around 450-480°C (842-896°F). Temperature Coefficients: Ferrite magnets have a relatively low temperature coefficient of magnetic remanence (Br) and coercivity (Hc). This means that while their magnetic properties are affected by temperature changes, the impact is relatively small compared to some other types of magnets. When design ferrite magnets in applications that involve temperature extremes, it's crucial to consider the potential impact on the magnet's performance and to choose a grade that suits the specific temperature conditions of the application.

Beyond Ferrite, our material expertise spans a diverse range, incorporating cutting-edge alloys and composites. We harness materials with precision to craft solutions that meet the unique demands of modern applications.

Recognizing the varied needs of industries, we offer more than off-the-shelf products. Our customization prowess allows us to tailor magnetic solutions, optimizing size, shape, and magnetic strength to align seamlessly with specific project requirements.

We are not merely suppliers but collaborators in innovation. Our team works closely with clients to integrate magnetic solutions seamlessly into their designs. From automotive applications to medical devices, our magnets are seamlessly woven into the fabric of modern technological advancements.

Adapting to the ever-evolving landscape of industry challenges, we stay at the forefront of research and development. Our commitment to staying abreast of emerging technologies ensures that our solutions remain not only current but also ahead of the curve.

AEMagnets is focus on creating values for our customer with innovative solution, supporting various industries through advanced magnetic technology.

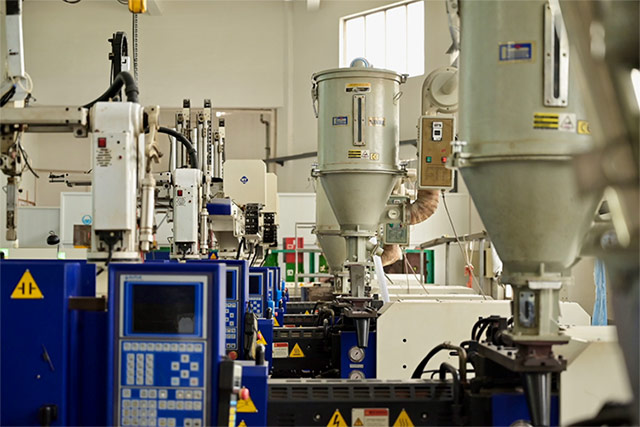

With 20 years of technical magnet expertise, AEMagnets is uniquely qualified in all aspects of magnets engineering and manufacturing. We will work with our customer to achieve an optimized magnetic solution for virtually any need focus on quality, application, cost, lead time. Engineering is core of our business. We've found that concurrent engineering from early start of a project yields the best overall results, which is why we like to work with our customers from the very beginning on major projects by utilizing our highly-skilled technical experts, in our company we call it Early Involvement of Engineering(EIE).

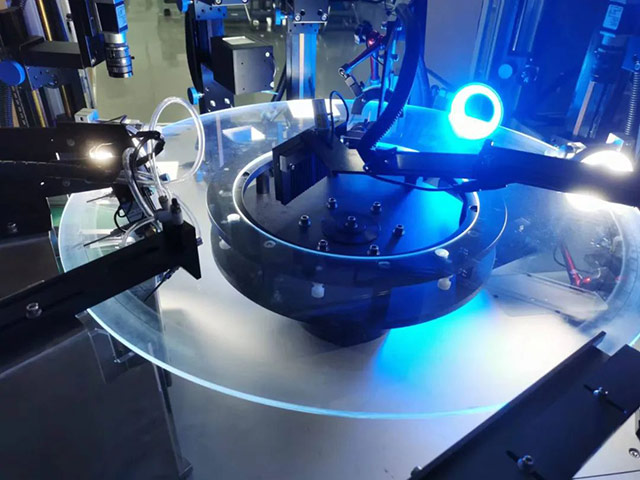

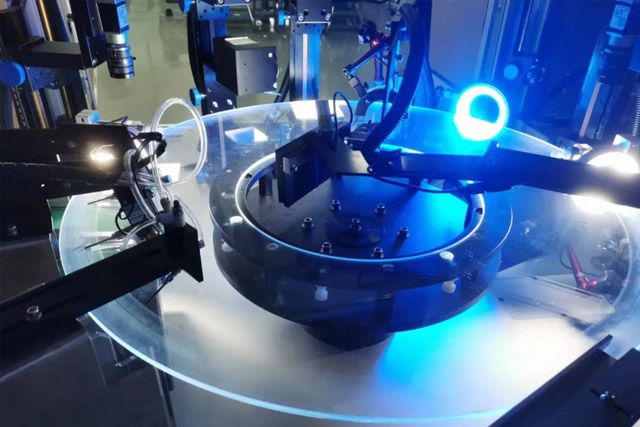

As a licensed and certified magnet manufacturer, we use high level inspection equipment and testing methods to ensure that our supplied products can meet customer requirements. Besides we also conduct quality planning from very beginning as to mitigate risk from virtual to real production. If there is complaint happened we will treat serious and use 8D methodology to make a thoroughly investigation and also set preventive actions, by insist on this our quality keeps on a very high level, which will finally return back to our customer’s trust.

Insist to pursue continuous improvement for cost management through lean production & supply chain management, etc., keep price competitive and share interests with customer.

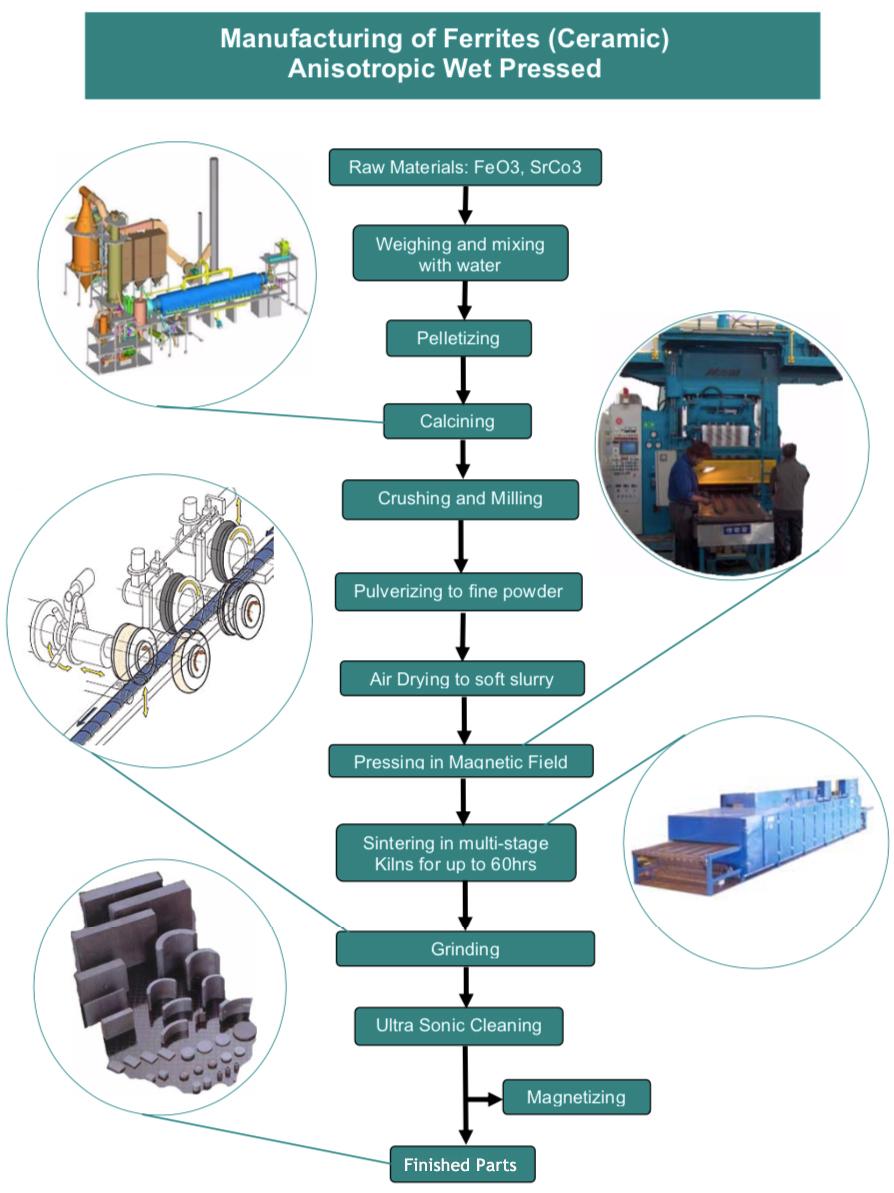

Ferrite magnets, also known as ceramic magnets, are a type of permanent magnet made from a compound of iron oxide (Fe2O3) combined with other elements like strontium carbonate (SrCO3) or barium carbonate (BaCO3). Ferrite magnets are well know with their characteristic as low cost, good corrosion resistance(can be used in water without corrosion at all) and high temperature stability up to 250°C, although they are less magnetic, they are more resistant to demagnetization than other magnets.

Ferrite magnets are typically classified into different grades based on their magnetic properties. The grading system for ferrite magnets usually involves alphanumeric codes to represent the specific characteristics of the magnet. The grades generally include a combination of letters and numbers.

Here are some common examples:

C Grades (C1, C5, C8, etc.):

These grades are associated with ceramic (ferrite) magnets. The number following the letter "C" represents the magnetic energy product (BHmax) of the magnet. Higher numbers indicate higher magnetic energy products. For example, C8 has a higher energy product than C5.

Y Grades (Y20, Y30, Y35, etc.):

The "Y" grades are also used for ferrite magnets, and like the "C" grades, they indicate different levels of magnetic energy product. Again, higher numbers correspond to higher energy products.

Hard Ferrite Grades (e.g., HF26/18):

Some manufacturers use specific designations to represent the magnetic properties of their ferrite magnets. In this example, "HF26/18" might denote a hard ferrite magnet with a magnetic energy product of 26 Mega-Gauss-Oersteds (MGOe) and a intrinsic coercivity (Hci) of 18 kiloOersteds

Ferrite magnets do not necessarily need to be plated for functional purposes, as they are relatively corrosion-resistant compared to some other types of magnets

Two common methods are used to measure the magnetic strength of magnets: Gauss testing and Pull testing.

Gauss Testing: Gauss measurement gauges a magnet's field strength using a device called a gauss meter.

Pull Testing: This method measures the force required to detach a known ferrous object from the magnet's surface.

The choice between these methods depends on the specific requirements of the application and the accuracy needed. Pull testing is often preferred for its practicality and ease of use, especially in scenarios where reliability and repeatability are crucial, such as in quality control programs.

Ferrite magnets are considered to be very stable and have excellent resistance to demagnetization under normal environmental conditions. They are classified as hard magnets because of their high coercivity, which means they require a significant amount of external magnetic field strength to demagnetize them.

In practical terms, ferrite magnets exhibit minimal natural decay or loss of strength over time when used in standard operating conditions. However, there are a few factors that could potentially contribute to a reduction in magnetic strength over an extended period.

Extreme Temperatures: Prolonged exposure to extreme temperatures, either very high or very low, can affect the magnetic properties of ferrite magnets. In high temperatures, the magnetic domains may become more disordered, leading to a temporary reduction in magnetic strength. Extreme cold temperatures may also impact the magnet's performance.

Physical Damage: Physical damage, such as chipping or cracking, can compromise the structural integrity of the magnet and may result in a reduction of its magnetic strength. Care should be taken to avoid subjecting ferrite magnets to excessive mechanical stress.

Corrosion: While ferrite magnets are generally resistant to corrosion, exposure to harsh chemical environments over an extended period could potentially affect their performance.

Radiation Exposure: In certain situations, exposure to high levels of radiation might impact the magnetic properties of ferrite magnets. This is more relevant in specialized applications and is not typically a concern in everyday use.

It's important to note that these factors usually apply over a long period, and under normal operating conditions, ferrite magnets are known for their stability and durability. Proper care and adherence to recommended operating conditions will help ensure the long-term performance of ferrite magnets

Ferrite magnets are considered safe for the human body. They are non-toxic and do not pose health risks when used properly. Ferrite magnets are composed mainly of iron oxide (Fe2O3), which is a form of iron that is found in many natural sources and is commonly used in dietary supplements. However, while the materials themselves are safe, caution should be exercised when handling strong magnets, regardless of their type. Here are a few considerations: Physical Injury: Ferrite magnets, like any strong magnets, can cause injuries if mishandled. They can attract each other with a significant force, and if fingers or other body parts get caught between them, it can lead to pinching or bruising. Additionally, larger and more powerful ferrite magnets can create strong magnetic fields, and if two magnets snap together unexpectedly, they can pinch the skin.

Ingestion Hazard: Small, loose magnets can be a choking hazard for small children, and if swallowed, they can cause serious health issues. Keep small magnets out of reach of young children, and if multiple magnets are swallowed, seek medical attention immediately.

Electronics and Medical Devices: Strong magnets can interfere with electronic devices and medical implants, such as pacemakers or defibrillators. Individuals with medical implants should consult with their healthcare providers before coming into close contact with strong magnets.

In summary, while the materials used in ferrite magnets are generally safe, proper handling and caution are essential, especially when dealing with strong or small magnets. It's crucial to follow safety guidelines provided by manufacturers and to be mindful of the potential risks associated with magnet use, particularly in certain environments or for specific individuals with medical devices.

Let us be your partner in magnets supply chain

| Grade | Br | HCB | HCJ | BH max | ||||

|---|---|---|---|---|---|---|---|---|

| mT | KGauss | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | |

| Y8T | 200~235 | 2.0~2.35 | 125-160 | 1.57-2.01 | 210-280 | 2.64-3.51 | 6.5-9.5 | 0.8-1.2 |

| Y22H | 310~360 | 3.10~3.60 | 220-250 | 2.76-3.14 | 280-320 | 3.51-4.02 | 20.0-24.0 | 2.5-3.0 |

| Y25 | 360~400 | 3.60~4.00 | 135-170 | 1.70-2.14 | 140-200 | 1.76-2.51 | 22.5-28.0 | 2.8-3.5 |

| Y26H-1 | 360~390 | 3.60~3.90 | 200-250 | 2.51-3.14 | 225-255 | 2.83-3.20 | 23.0-28.0 | 2.9-3.5 |

| Y26H-2 | 360~380 | 3.60~3.80 | 263-288 | 3.30-3.62 | 318-350 | 3.99-4.40 | 24.0-28.0 | 3.0-3.5 |

| Y27H | 350~380 | 3.50~3.80 | 225-240 | 2.83-3.01 | 235-260 | 2.95-3.27 | 25.0-29.0 | 3.1-3.6 |

| Y28 | 370~400 | 3.70~4.00 | 175-210 | 2.20-3.64 | 180-220 | 2.26-2.76 | 26.0-30.0 | 3.3-3.8 |

| Y28H-1 | 380~400 | 3.80~4.00 | 240-260 | 3.01-3.27 | 250-280 | 3.14-3.52 | 27.0-30.0 | 3.4-3.8 |

| Y28H-2 | 360~380 | 3.60~3.80 | 271-295 | 3.40-3.70 | 382-405 | 4.80-5.08 | 26.0-30.0 | 3.3-3.8 |

| Y30H-1 | 380~400 | 3.80~4.00 | 230-275 | 2.89-3.46 | 235-290 | 2.95-3.64 | 27.0-32.5 | 3.4-4.1 |

| Y30H-2 | 395~415 | 3.95~4.15 | 275-300 | 3.45-3.77 | 310-335 | 3.89-4.20 | 27.0-32.0 | 3.4-4.0 |

| Y32 | 400~420 | 4.00~4.20 | 160-190 | 2.01-2.39 | 165-195 | 2.07-2.45 | 30.0-33.5 | 3.8-4.2 |

| Y32H-1 | 400~420 | 4.00~4.20 | 190-230 | 2.39-2.89 | 230-250 | 2.89-3.14 | 31.5-35.0 | 3.9-4.4 |

| Y32H-2 | 400~440 | 4.00~4.40 | 224-240 | 2.81-3.01 | 230-250 | 2.89-3.14 | 31.0-34.0 | 3.9-4.3 |

| Y33 | 410~430 | 4.10~4.30 | 220-250 | 2.76-3.14 | 225-255 | 2.83-3.20 | 31.5-35.0 | 3.9-4.4 |

| Y33H | 410~430 | 4.10~4.30 | 250-270 | 3.14-3.39 | 250-275 | 3.14-3.45 | 31.5-35.0 | 3.9-4.4 |

| Y34 | 420~440 | 4.20~4.40 | 200-230 | 2.51-2.89 | 205-235 | 2.57-2.95 | 32.5-36.0 | 4.1-4.4 |

| Y35 | 430~450 | 4.30~4.50 | 215-239 | 2.70-3.00 | 217-241 | 2.73-3.03 | 33.1-38.2 | 4.1-4.8 |

| Y36 | 430~450 | 4.30~4.50 | 247-271 | 3.10-3.40 | 250-274 | 3.14-3.44 | 35.1-38.3 | 4.4-4.8 |

| Y38 | 440~460 | 4.40~4.60 | 285-305 | 3.58-3.83 | 294-310 | 3.69-3.89 | 36.6-40.6 | 4.6-5.1 |

| Y40 | 440~460 | 4.40~4.60 | 330-354 | 4.15-4.45 | 340-360 | 4.27-4.52 | 37.6-41.8 | 4.7-5.2 |

Ferrite magnets, also known as ceramic magnets, are a type of permanent magnet made from a compound of iron oxide (Fe2O3) combined with other elements like strontium carbonate (SrCO3) or barium carbonate (BaCO3). Ferrite magnets are well know with their characteristic as low cost, good corrosion resistance(can be used in water without corrosion at all) and high temperature stability up to 250°C, although they are less magnetic, they are more resistant to demagnetization than other magnets.

Ferrite magnets find applications in various industries and products due to their cost-effectiveness, stability, and resistance to demagnetization. Some common applications include:

Ferrite magnets, offer several advantages that make them suitable for a variety of applications. Here are some of the key advantages of ferrite magnets:

Ferrite magnets are generally more affordable than other types of magnets such as neodymium magnets. This makes them an economical choice for applications where high magnetic strength is not a primary requirement.

Ferrite magnets are classified as hard magnets, meaning they have high coercivity and are resistant to demagnetization. They provide a stable and reliable magnetic field over time.

Ferrite magnets have excellent corrosion resistance, making them suitable for applications in environments where exposure to moisture or corrosive substances is a concern.

The materials used in ferrite magnets, such as iron oxide and carbonates, are non-toxic and safe for use in various applications. They do not pose health risks to humans.

Ferrite magnets are available in various shapes and sizes, including discs, rings, blocks, and cylinders. This versatility allows for customization to meet specific design requirements.

Ferrite magnets find applications in a diverse range of industries, including electronics, automotive, audio equipment, medical devices, and more. Their versatility makes them suitable for various purposes.

Ferrite magnets are easily magnetized in different patterns, allowing for the creation of complex magnetic assemblies and structures to suit specific applications.

Ferrite magnets are electrically insulating, making them suitable for applications where electrical conductivity is not desired.

Ferrite magnets are mass-produced and readily available in the market. Their widespread availability contributes to their cost-effectiveness and accessibility. While ferrite magnets have these advantages, it's essential to recognize that they may not be suitable for applications requiring extremely high magnetic strength. In such cases, other types of magnets like neodymium magnets might be preferred. The choice of magnet depends on the specific needs and constraints of the application.

lf you're looking for Ferrite magnets, we'll work with you to find the best option for your appilaction.

When purchasing Ferrite magnets, several specifications and parameters need to be considered to ensure that the magnets meet the specific requirements of your application. Here are some key specifications to consider:

Gauss measurement gauges a magnet's field strength using a device called a gauss meter.

Process: A handheld probe of the gauss meter is moved around the magnet, and the values increase or decrease accordingly.

Limitations: Gauss meters are highly sensitive, making it challenging to obtain reliable, repeatable values. Calibration issues are common, and even slight movements of the probe can yield different results.

Application: Provides insights into a magnet's circuit design and field gradient but may not be the preferred method due to its sensitivity.

This method measures the force required to detach a known ferrous object from the magnet's surface.

Process: A ferrous object (usually a steel ball) is placed on the magnet's surface, and the force needed for detachment is measured, typically in pounds or ounces.

Application: Effective in determining a magnet's strength, especially for magnets capturing metals from a distance away. It also allows measurement of the magnet's gradient with non-ferrous spacers.

Advantages: Often favored for its reliability and repeatability, particularly in stringent quality programs.

Normally the Ferrite magnets can be shipped by air, sea, railway, land, depends on weight and distance, before shipping the magnets need to be packed with magnetic shield to make sure the magnetism can not affect outside of the package. Magnetic inspection is necessary for air shipping which is conducted by 3rd party, meanswhile MSDS report is necessary for sea shipping.

Navigating the realm of Ferrite magnets can be overwhelming, especially for newcomers. Yet, with invaluable insights into Ferrite magnets, the complexity of selection transforms into a streamlined process. Backed by decades of expertise in the Ferrite magnets sector, AEMagnets stands as a reliable source for optimal materials grades, size, shapes, and specifications catering to projects of any scale. Our dedicated team is ready to provide insightful guidance, with the added convenience of customizable samples meticulously crafted to suit your distinct requirements. Trust in AEMagnets for a seamless Ferrite magnets selection experience.