Are you looking for a reliable AlNiCo magnets manufacturer, are you searching for the strongest magnets for your application, or even expecting design for your own specificiation, I am glad you have come to the right place. With over 20 years design and manufacturing experience, AEMagnets is a leading AlNiCo magnets supplier, serve to different industies with various sizes and shapes. Applications such as guitar pickups, MRI, rotor, the highest working temperatures up to 550 degree.

Are you eager to explore more about us, are you ready to discuss with us, let's start!

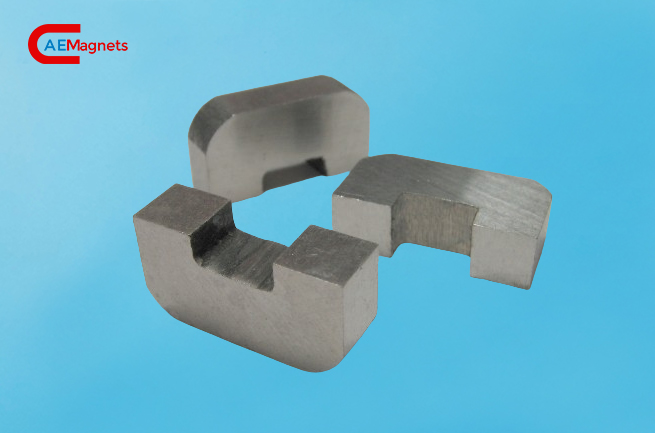

AlNiCo 450 with size of Diameter 15*11.9mm, soft iron outside

AlNiCo 450 with 10.98*7.6*3.5mm

AlNiCo 5 with 22*8*5.5mm

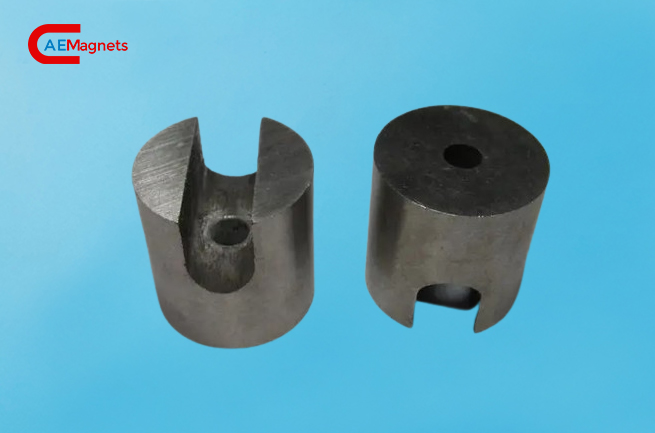

AlNiCo 5 with Diameter 12*16mm with hole 3mm

AlNiCo 2 with 25*10*6mm

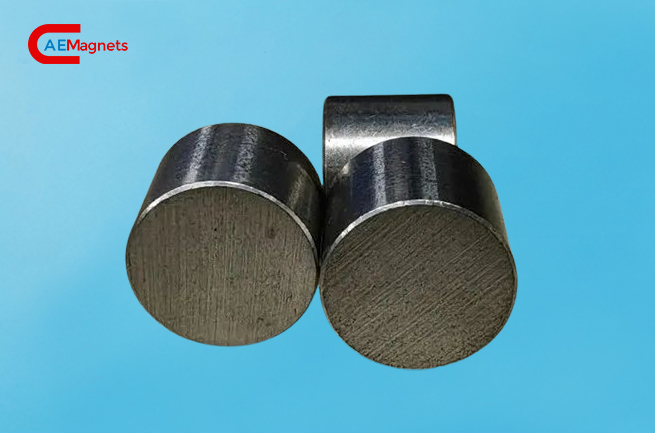

AlNiCo 8 with Diameter 6*10mm

AlNiCo 8 with Diameter 14*8mm

At AEMagnets, we understand every customer has individual needs and specifictions for the AlNiCo magnets, that's why we insit on customize for our client, not only for design but also for the manufacruring and service.

Grades & magnetic strength:

We provide a wide range of grades:

AlNiCo 5: This is one of the most widely used grades of AlNiCo magnets, often used in applications such as guitar pickups.

AlNiCo 2: This grade has a lower magnetic strength compared to AlNiCo 5. It is sometimes preferred for certain applications where a softer magnetic field is desirable, such as in specific types of pickups for musical instruments.

AlNiCo 8: This grade has a higher magnetic strength than AlNiCo 5. It is used in applications where a stronger magnetic field is required, such as in some specialized industrial applications.

AlNiCo 9: AlNiCo 9 is a less common grade that offers a balance between magnetic strength and temperature stability. It may be used in applications where both factors are important.

Beyond AlNiCo, our material expertise spans a diverse range, incorporating cutting-edge alloys and composites. We harness materials with precision to craft solutions that meet the unique demands of modern applications.

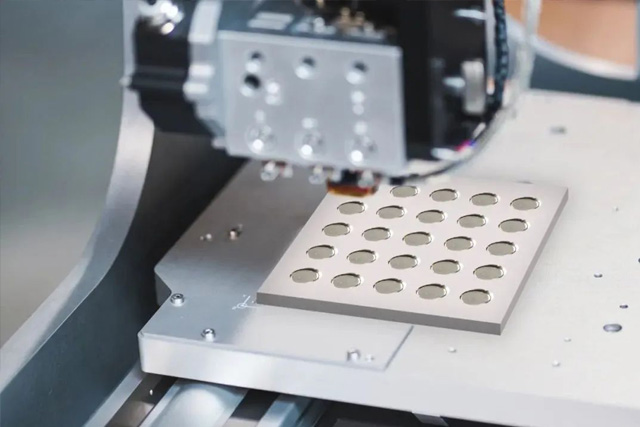

Recognizing the varied needs of industries, we offer more than off-the-shelf products. Our customization prowess allows us to tailor magnetic solutions, optimizing size, shape, and magnetic strength to align seamlessly with specific project requirements.

We are not merely suppliers but collaborators in innovation. Our team works closely with clients to integrate magnetic solutions seamlessly into their designs. From automotive applications to medical devices, our magnets are seamlessly woven into the fabric of modern technological advancements.

Adapting to the ever-evolving landscape of industry challenges, we stay at the forefront of research and development. Our commitment to staying abreast of emerging technologies ensures that our solutions remain not only current but also ahead of the curve.

AEMagnets is focus on creating values for our customer with innovative solution, supporting various industries through advanced magnetic technology.

With 20 years of technical magnet expertise, AEMagnets is uniquely qualified in all aspects of magnets engineering and manufacturing. We will work with our customer to achieve an optimized magnetic solution for virtually any need focus on quality, application, cost, lead time.

Engineering is core of our business. We've found that concurrent engineering from early start of a project yields the best overall results, which is why we like to work with our customers from the very beginning on major projects by utilizing our highly-skilled technical experts, in our company we call it Early Involvement of Engineering(EIE).

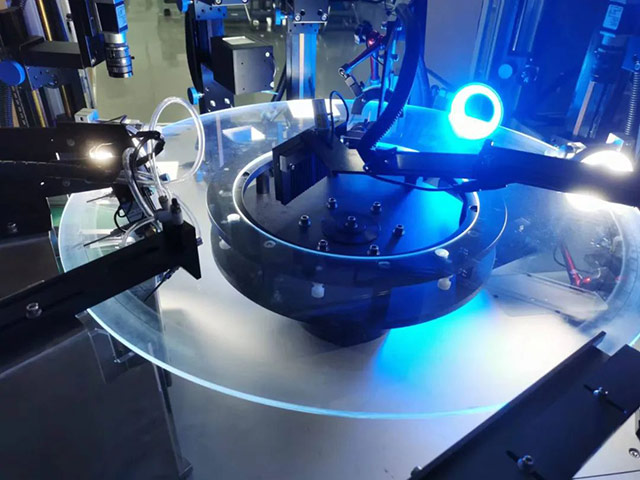

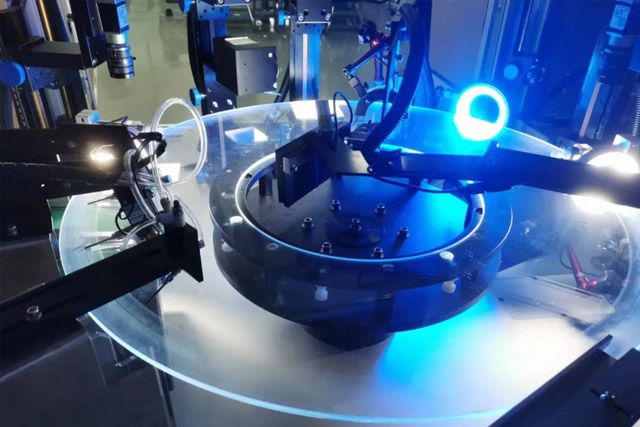

As a licensed and certified magnet manufacturer, we use high level inspection equipment and testing methods to ensure that our supplied products can meet customer requirements. Besides we also conduct quality planning from very beginning as to mitigate risk from virtual to real production. If there is complaint happened we will treat serious and use 8D methodology to make a thoroughly investigation and also set preventive actions, by insist on this our quality keeps on a very high level, which will finally return back to our customer’s trust.

Insist to pursue continuous improvement for cost management through lean production & supply chain management, etc., keep price competitive and share interests with customer.

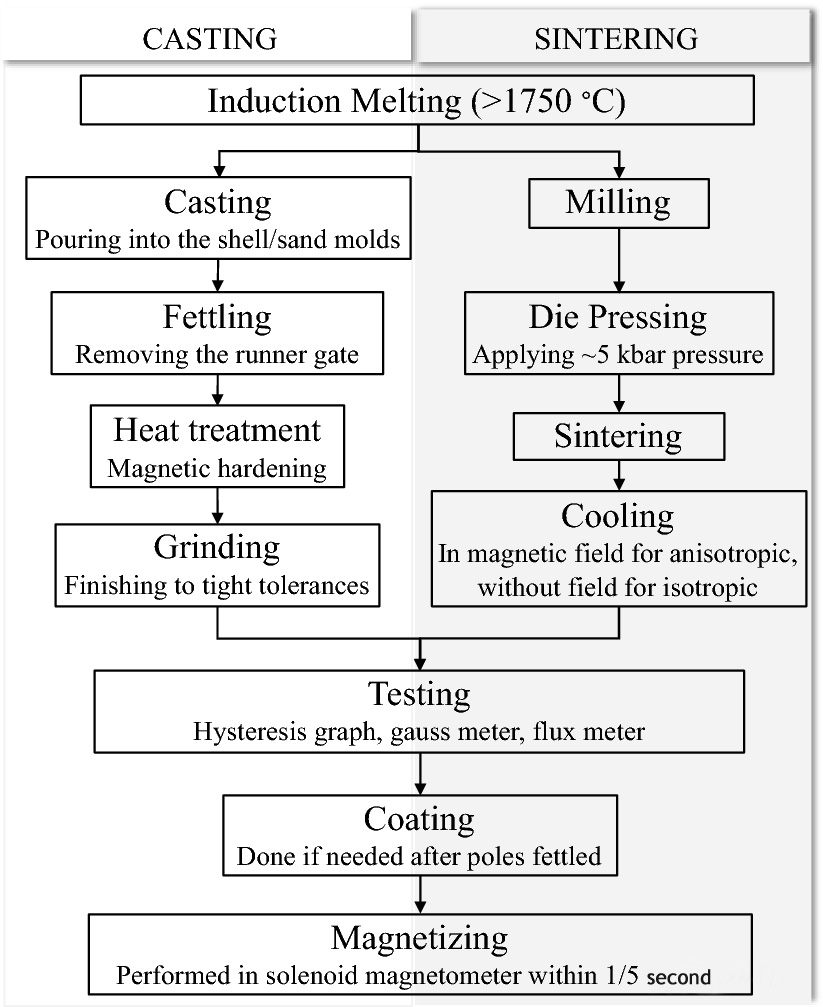

AlNiCo magnets, short for aluminum-nickel-cobalt magnets, which was discovered in 1931 by T. Mishima in Japan, are a type of permanent magnet that consists of aluminum (Al), nickel (Ni), and cobalt (Co), along with iron and other elements. These magnets are known for their strong magnetic properties and are used in various applications such as electric motors, generators, loudspeakers, sensors, and more. According to manufacuring process AlNiCo magnets can be divided into cast AlNiCo, sintered AlNiCo, and bonded AlNiCo, totally is 17 cast, 10 sintered, and 2 bonded.

The composition of AlNiCo alloys is typically 8–12% Al, 15–26% Ni, 5–24% Co, up to 6% Cu, up to 1% Ti, and the rest is Fe.

AlNiCo magnets are classified based on their composition and magnetic properties. The most common grades of AlNiCo magnets include:

The numbers assigned to the grades (e.g., 5, 2, 8, 9) generally indicate the magnetic strength of the material. The higher the number, the stronger the magnet. It's important to note that while AlNiCo magnets exhibit good temperature stability, their magnetic strength can be influenced by temperature changes.

AlNiCo magnets do not necessarily need to be plated for functional purposes, as they are relatively corrosion-resistant compared to some other types of magnets.

Two common methods are used to measure the magnetic strength of magnets: Gauss testing and Pull testing.

Gauss Testing: Gauss measurement gauges a magnet's field strength using a device called a gauss meter.

Pull Testing: This method measures the force required to detach a known ferrous object from the magnet's surface.

The choice between these methods depends on the specific requirements of the application and the accuracy needed. Pull testing is often preferred for its practicality and ease of use, especially in scenarios where reliability and repeatability are crucial, such as in quality control programs.

AlNiCo magnets have good resistance to demagnetization and maintain their magnetic strength well. However, there are factors that can affect the performance of AlNiCo magnets over time:

Mechanical Shock: Excessive mechanical shock or impact can lead to irreversible demagnetization in AlNiCo magnets. Care should be taken to avoid subjecting the magnets to severe mechanical stresses.

In general, AlNiCo magnets are known for their long-term stability, and their magnetic properties can be maintained over extended periods, especially when used within their specified operating conditions. Regular monitoring of the operating environment and proper handling can contribute to the longevity of AlNiCo magnets. If specific concerns arise or if there are changes in the operating conditions, it's advisable to consult with magnet manufacturers or experts for guidance on maintaining optimal performance

AlNiCo magnets are generally considered safe for most normal uses and interactions with the human body. AlNiCo magnets are not as prone to breakage or chipping, which reduces the risk of injury due to small, sharp fragments. However, it's important to handle magnets of any kind with care to avoid potential hazards. Here are some considerations:

If you have specific concerns about the safety of AlNiCo magnets in a particular application or environment, it's advisable to consult with our experts or relevant safety guidelines. In general, following safe handling practices and keeping magnets away from small children or individuals with medical devices is recommended.

Let us be your partner in magnets supply chain

| Alnico magnets Comparision | Manufacturing Process | Grain Structure | Applications | Advantage |

|---|---|---|---|---|

| Cast Alnico magnets | Produced by casting a molten metal alloy into molds. | Directional or anisotropic grain structure, with high magnetic strength and excellent magnetic orientation. | High magnetic strength and complex shapes are required, such as electric motors, sensors, and magnetic couplings. | Complex shapes, suitable for custom applications.Good mechanical strength but may be more brittle compared to sintered Alnico magnets.Exhibit higher magnetic strength compared to sintered or bonded Alnico magnets. |

| Sintered Alnico magnets | Produced through a powder metallurgy process involving compacting fine Alnico powder in a press and sintering the compacted material. | Random or isotropic grain structure, leading to slightly lower magnetic properties compared to cast Alnico magnets. | A balance between magnetic performance and manufacturing tolerances is essential. | Better dimensional tolerances than cast Alnico magnets. |

| Bonded AlNiCo magnets | Produced by mixing AlNiCo powder with a binder and then compressing the mixture into a desired shape. | Non-oriented or isotropic grain structure. | Complex shapes, close tolerances, and moderate magnetic strength are required, such as in sensors and magnetic assemblies | Good dimensional accuracy and can be manufactured with intricate shapes. |

| USA Standard | Grade | Remanence Induction | Coercive Force | Maximum Energy Product | Density | Reversible Temp. Coefficient | Reversible Temp. Coefficient | Curie Temp. | Working Temp. | Remark | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Br | HcB | (BH)max | ρ | %°c | %°c | Tc | Tw | ||||||

| MMPA | mT | Gs | kA/m | Oe | KJ/m³ | MGOe | g/cm3 | ℃ | ℃ | ||||

| AlNiCo3 | LN10 | 600 | 6000 | 40 | 500 | 10 | 1.2 | 6.9 | -0.03 | -0.02 | 810 | 450 | Isotropy |

| AlNiCo2 | LNG13 | 700 | 7000 | 48 | 600 | 12.8 | 1.6 | 7.2 | -0.03 | +0.02 | 810 | 450 | |

| AlNiCo8 | LNGT18 | 580 | 5800 | 100 | 1250 | 18 | 2.2 | 7.3 | -0.025 | +0.02 | 860 | 550 | |

| AlNiCo5 | LNG37 | 1200 | 12000 | 48 | 600 | 37 | 4.65 | 8.3 | -0.025 | +0.02 | 850 | 525 | Anisotropy |

| LNG40 | 1250 | 12500 | 48 | 600 | 40 | 5 | 9.3 | -0.02 | +0.02 | 850 | 525 | ||

| LNG44 | 1250 | 12500 | 52 | 650 | 44 | 5.5 | 10.3 | -0.02 | +0.02 | 850 | 525 | ||

| AlNiCo5DG | LNG52 | 1300 | 13000 | 56 | 700 | 52 | 6.5 | 11.3 | -0.02 | +0.02 | 850 | 525 | |

| AlNiCo5-7 | LNG60 | 1350 | 13500 | 59 | 740 | 60 | 7.5 | 12.3 | -0.02 | +0.02 | 850 | 525 | |

| AlNiCo6 | LNGT28 | 1000 | 10000 | 57.6 | 720 | 28 | 3.5 | 13.3 | -0.02 | +0.02 | 850 | 525 | |

| AlNiCo8HC | LNGT36J | 700 | 7000 | 140 | 1750 | 36 | 4.5 | 14.3 | -0.02 | +0.02 | 860 | 550 | |

| LNGT40J | 750 | 7500 | 144 | 1800 | 40 | 5 | 15.3 | -0.025 | +0.02 | 860 | 550 | ||

| AlNiCo8 | LNGT38 | 800 | 8000 | 110 | 1380 | 38 | 4.75 | 16.3 | -0.025 | +0.02 | 860 | 550 | |

| LNGT40 | 820 | 8200 | 110 | 1380 | 40 | 5 | 17.3 | -0.025 | +0.02 | 860 | 550 | ||

| LNGT44 | 850 | 8500 | 120 | 1500 | 44 | 5.5 | 18.3 | -0.025 | +0.02 | 860 | 550 | ||

| AlNiCo9 | LNGT60 | 900 | 9000 | 110 | 1380 | 60 | 7.5 | 19.3 | -0.025 | +0.02 | 860 | 550 | |

| LNGT72 | 1050 | 10500 | 112 | 1400 | 72 | 9 | 20.3 | -0.025 | +0.02 | 860 | 550 | ||

| LNGT80 | 1080 | 10800 | 120 | 1500 | 80 | 10 | 21.3 | -0.025 | +0.02 | 860 | 550 | ||

| LNGT88 | 1100 | 11000 | 120 | 1500 | 88 | 11 | 22.3 | -0.025 | +0.02 | 860 | 550 | ||

| LNGT92 | 1120 | 11200 | 120 | 1500 | 92 | 11.5 | 23.3 | -0.025 | +0.02 | 860 | 550 | ||

| LNGT96 | 1150 | 11500 | 120 | 1500 | 96 | 12 | 24.3 | -0.025 | +0.02 | 860 | 550 | ||

AlNiCo magnets, short for aluminum-nickel-cobalt magnets, which was discovered in 1931 by T. Mishima in Japan, are a type of permanent magnet that consists of aluminum (Al), nickel (Ni), and cobalt (Co), along with iron and other elements. These magnets are known for their strong magnetic properties and are used in various applications such as electric motors, generators, loudspeakers, sensors, and more. According to manufacuring process AlNiCo magnets can be divided into Cast AlNiCo and Sintered AlNiCo.

AlNiCo magnets find application in various industries and products due to their strong magnetic properties and durability, applications of AlNiCo magnets include:

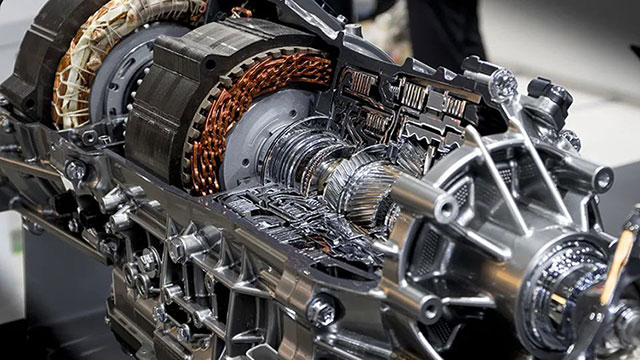

Electric Motors and Generators:

AlNiCo magnets are used in the construction of electric motors and generators, where their strong magnetic fields contribute to efficient energy conversion.

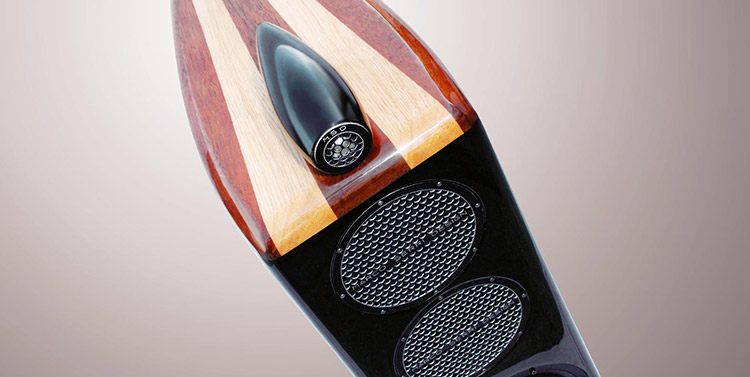

Loudspeakers:

AlNiCo magnets have historically been used in the production of high-quality loudspeakers. Their magnetic strength is crucial for converting electrical signals into sound waves.

Guitar Pickups:

AlNiCo magnets are commonly used in the construction of guitar pickups. Different grades of AlNiCo magnets can influence the tone and performance of the guitar.

Sensors:

AlNiCo magnets are used in various sensor applications, such as magnetic field sensors and reed switches, where their stable magnetic properties are beneficial.

Magnetic Separators:

AlNiCo magnets are employed in magnetic separators to remove ferrous contaminants from materials in industries such as mining and recycling.

Medical Instruments:

AlNiCo magnets may find applications in certain medical instruments, including magnetic resonance imaging (MRI) machines.

Scientific Instruments:

AlNiCo magnets can be used in various scientific instruments and research applications where a strong and stable magnetic field is required.

Education and Demonstrations:

AlNiCo magnets are often used in educational settings for demonstrations and experiments to showcase magnetic principles.

AlNiCo magnets, offer several advantages that make them suitable for specific applications. Some of the key advantages of AlNiCo magnets include:

Strong Magnetic Properties: AlNiCo magnets are known for their strong magnetic fields and high magnetic flux density. This makes them suitable for applications where a powerful and stable magnetic field is required.

Temperature Stability: AlNiCo magnets exhibit good stability over a wide range of temperatures. They can withstand high operating temperatures without significant loss of magnetic strength, making them suitable for applications in elevated temperature environments.

Durability and Longevity: AlNiCo magnets are durable and resistant to demagnetization under normal operating conditions. They have a high coercive force, which means they are less susceptible to becoming demagnetized by external magnetic fields.

Corrosion Resistance: AlNiCo magnets have good resistance to corrosion, which contributes to their longevity and reliability in various applications. However, in certain harsh environments, additional coating or plating may be applied for enhanced corrosion protection.

Versatility: AlNiCo magnets come in various grades (AlNiCo 2, AlNiCo 5, AlNiCo 8, etc.), allowing for versatility in meeting specific application requirements. Different grades offer variations in magnetic strength, coercivity, and other properties.

High Curie Temperature: AlNiCo magnets have a high Curie temperature, which is the temperature at which they lose their magnetic properties. This property makes them suitable for applications where exposure to elevated temperatures is common.

Good Mechanical Strength: AlNiCo magnets are relatively hard and have good mechanical strength, contributing to their durability in various applications.

Resistance to Demagnetization: AlNiCo magnets generally have a high resistance to demagnetization, which means they can maintain their magnetic strength over a long period, especially when used within their specified operating conditions.

Despite these advantages, the choice of magnet depends on the specific requirements of the application, including factors such as magnetic strength, temperature stability, and cost considerations

lf you're looking for AlNiCo Magnets, we'll work with you to find the best option for your appilaction.

Application Requirements:

Clearly communicate the specific requirements of your application, including the intended use, environmental conditions, and any performance criteria that must be met.

Grade:

AlNiCo magnets come in various grades, such as AlNiCo 2, AlNiCo 5, AlNiCo 8, etc. Each grade has different magnetic properties, including magnetic strength, coercivity, and temperature stability. Choose a grade that aligns with your application requirements.

Magnetic Properties:

Consider the desired magnetic properties such as magnetic flux density (measured in Gauss or Tesla), coercive force (Hc), and maximum energy product (BHmax). These properties will determine the magnet's performance in your application.

Shape and Size:

Determine the specific shape and size of the magnet needed for your application. AlNiCo magnets can be manufactured in various shapes, including discs, blocks, rings, and horseshoes. Specify the dimensions (length, width, thickness, diameter, etc.) according to your requirements.

Tolerance:

Specify the acceptable tolerance for the dimensions of the magnet. Tolerances are typically expressed as a percentage of the nominal dimension.

Temperature Rating:

Consider the operating temperature of your application. AlNiCo magnets have good temperature stability, but it's essential to choose a magnet with a temperature rating that aligns with your specific environmental conditions.

Coating or Plating:

Determine whether the magnets require any coating or plating for protection against corrosion or other environmental factors. Common coatings include nickel, zinc, or epoxy.

Budget Constraints:

Consider your budget constraints and seek options that balance cost with the required performance.

When in doubt or if you have specific application requirements, it's recommended to consult with our experts. We can provide guidance on selecting the right AlNiCo magnet for your needs and offer technical assistance to ensure the magnets perform optimally in your application.

Gauss measurement gauges a magnet's field strength using a device called a gauss meter.

Process: A handheld probe of the gauss meter is moved around the magnet, and the values increase or decrease accordingly.

Limitations: Gauss meters are highly sensitive, making it challenging to obtain reliable, repeatable values. Calibration issues are common, and even slight movements of the probe can yield different results.

Application: Provides insights into a magnet's circuit design and field gradient but may not be the preferred method due to its sensitivity.

This method measures the force required to detach a known ferrous object from the magnet's surface.

Process: A ferrous object (usually a steel ball) is placed on the magnet's surface, and the force needed for detachment is measured, typically in pounds or ounces.

Application: Effective in determining a magnet's strength, especially for magnets capturing metals from a distance away. It also allows measurement of the magnet's gradient with non-ferrous spacers.

Advantages: Often favored for its reliability and repeatability, particularly in stringent quality programs.

Normally the AlNiCo magnets can be shipped by air, sea, railway, land, depends on weight and distance, before shipping the magnets need to be packed with magnetic shield to make sure the magnetism can not affect outside of the package. Magnetic inspection is necessary for air shipping which is conducted by 3rd party, meanswhile MSDS report is necessary for sea shipping.

Navigating the realm of AlNiCo magnets can be overwhelming, especially for newcomers. Yet, with invaluable insights into AlNiCo magnets, the complexity of selection transforms into a streamlined process.

Backed by decades of expertise in the AlNiCo magnets sector, AEMagnets stands as a reliable source for optimal materials grades, size, shapes, and specifications catering to projects of any scale. Our dedicated team is ready to provide insightful guidance, with the added convenience of customizable samples meticulously crafted to suit your distinct requirements. Trust in AEMagnets for a seamless AlNiCo magnets selection experience.